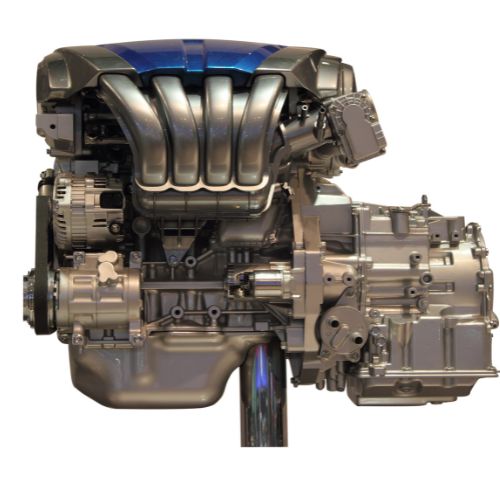

Reman 07-11 Jeep Wrangler 3.8 Long Block Engine

Large Network Of Engine Suppliers

Compare Quotes

Save Money

Save Time

Reman 07-11 Jeep Wrangler 3.8 Long Block Engine For Sale

If you are in the market for getting a excellent used Jeep engine for sale, look no further than Used Engine Finder. We allow you to promptly get in touch with a network of Jeep vehicle dismantlers and engine importers, so you can get the best deal for the ideal replacement engine for your needs.

Trying hard to find a motor is no longer necessary thanks to Used Engine Finder. Let us know what you’re trying to find, and our businesses get you various costs. You can be sure you’re getting the very best price since we work directly with them.

So don’t squander any more time and use Used Engine Finder to find the ideal engine for your Jeep.

- Used Engine Finder will let you save time and cash by finding the right engine for your Jeep.

- Receive several quotes from our honest traders.

- Deal directly with engine suppliers, ensuring you get the best price.

- You may find motors for just about any and all automobiles here.

Best Engine Replacement Procedure

- Swap the engine’s oil, fuel and oil filters, and coolant.

- Install new engine and external coolers if existing.

- Cleanse the cooling system thoroughly, then replace the water pump.

- Renew necessary hoses and belts.

- Install a new timing belt, spark plugs, and wires.

- Replace essential gaskets and seals, focusing on the oil pan, front, and rear main seals.

- Clear the vehicle’s computer codes before engine installation.

- Ensure the replacement engine matches the original specifications.

- Transfer exhaust manifolds, mounts, distributor, and sensors from the old engine.

- Disable fuel and ignition before ignition to prime the oil.

- Ensure no plugs or tape remain on the engine before installation.

7 Common Mistakes to AVOID!

- Not resetting the vehicle’s computer codes before installation.

- Skipping the step of adding engine oil before the first startup.

- Forgetting to deactivate the fuel and ignition systems, essential for priming the oil.

- Ignoring the replacement of the oil cooler or the radiator’s integrated oil cooler.

- Overlooking the cleaning of the radiator and checking the operation of the cooling fans.

- Not swapping out the flywheel and its securing bolts.

- Trying to initiate the engine’s first run without proper priming.